Powered fiber cable drives video security

High-definition video cameras are increasingly popular as a means to secure sites such as hospitals and university campuses, but evolution in camera technology and the demands of specific venues are driving changes in the cabling systems used to connect these cameras. The need to bring power and high-bandwidth data resources to every camera in a broad-based deployment often means high construction costs and suboptimal placement of cameras. In this article, we’ll look at the changing technology in surveillance cameras, how this impacts the type of cabling used to connect them, and how hybrid cable systems can support future deployments.

Rising demand for video security

According to Transparency Market Research, the demand for video surveillance systems is rising, expected to approach $40 billion USD by 2020. Similarly, securitysales.com predicts a market of $42 billion USD by 2019 with a compound annual growth rate for IP-based video surveillance in particular of 24.2 percent from 2013 to 2019.

Of course, market reports are only estimates, but all notable sources predict a continued increase in demand for video surveillance equipment. Many factors have been cited to explain the rise in demand for video security systems including, but not limited to, increased threat of terrorism, crime/violence prevention, the rise in the “Internet of Things” (IoT), and new applications such as commercial advertising (Imagine as you walk into a mall the system “recognizes” you, allowing delivery of various context-appropriate advertising tailored to your typical buying habits).

Changing camera technology

In the past, lower-resolution analog security cameras have been widely deployed. But the quality of the video in these 920H and lower resolution cameras is far lower than the new wave of IP-based high-definition (HD) video cameras (meaning cameras with resolution of at least 720p).

HD video cameras support 720p (720 vertical lines) or 1080p resolution. But, even higher resolution is always better in surveillance video because it allows those monitoring the video feed to see smaller objects, or to see people, license plate numbers, and other elements more clearly. With the advent of 4K video standards, security cameras are now supporting 3840 pixels by 2160 lines, or 2160p resolution, and camera makers are already experimenting with 8K video to once again double a camera’s resolution.

4K video cameras are already making significant improvements in security. With high resolution, these cameras can be placed at considerable distances from the area they monitor and still allow digital zoom to pick up small objects. In one instance, a camera located two miles from a city center can be digitally zoomed to pick up license plate numbers.

In addition, sites are enhancing security by using low-cost facial recognition servers to process the video feed. One customer recently cited to us that for as little as $6,000, users can deploy a facial recognition server and integrate this into the video camera control system (network video recorder) to provide quick identification of suspicious people.

With higher resolution comes the need for higher bandwidth. Yesterday’s video cameras could be connected with coaxial cable because they needed fairly low bandwidth. Some estimates are that a single 4K camera video feed, with modern video compression, needs about 15 Mbits/sec minimum of bandwidth (without video compression the bandwidth need is much higher). If one imagines a campus deployment with many cameras, then the bandwidth demand begins to add up. According to ABI Research, The Video Surveillance Report, 2010, the average Las Vegas casino has more than 2,000 cameras. By itself, this still might not absolutely require a move to optical fiber as the communications medium, however when the distances from head-end locations to these cameras are factored in, optical fiber begins to be attractive as opposed to traditional copper-based solutions.

The need for bandwidth and power

But in addition to bandwidth, video cameras also need a source of power, and this can be problematic. Colleges, for example, want to deploy cameras on light poles around campus, but those poles are often in power-off mode during daylight hours (controlled by photocells), so they cannot always provide 24-hour power to video cameras. In other venues, cameras may be placed on the sides of buildings or on utility poles, but in these cases the camera owner may have to negotiate access to power from the building owner or utility and may have to pay for that power on a monthly basis.

If the decision is taken to tap into local power, then the cameras are themselves subject to the reliability of that local power source. To counteract this, network operators sometimes want to install local uninterruptible power supply (UPS) batteries, but these remote batteries are difficult and expensive to maintain.

IEEE ratified a standard for delivering both power and data in a single Ethernet cable; it is called Power over Ethernet, or PoE. The standards 802.3af (PoE) and 802.3at (PoE Plus) define how power and data can be delivered at distances up to 100 meters via category cabling. More than a simple direct current (DC) power solution, the PoE standard incorporates excellent safety features, software handshaking, etc. into a truly useful solution.

The broad placement of video cameras throughout a campus or other facility means that cameras can be hundreds of meters from the video head end. In fact, if very long distances can be supported, it becomes possible to reduce the number of head-end locations, further saving capital expenses and operating expenses. As a result, installers will often want to use optical fiber to form connections. Singlemode fiber can carry nearly unlimited data, so it is more than ample for connecting 4K or 8K cameras, and its reach can extend for miles. Multimode fiber, especially newer 50-micron core-size Om3 and Om4 fibers, can handle distances in the “hundreds of meters” range and so is also a viable option for many situations.

Powered fiber cable systems

So fiber is a great option for handling long-distance data transmission, but what about also delivering power?

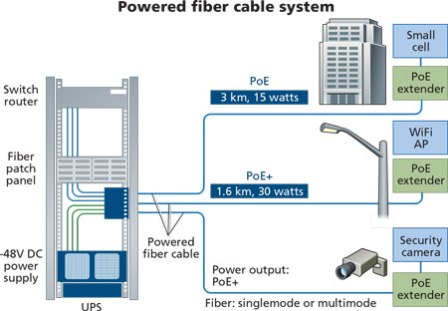

A powered fiber cable system (PFCS) addresses the need for local power as well as the need for fiber data connectivity. The PFCS incorporates a rack-mounted power and optical-fiber termination point, a hybrid cable that includes both singlemode and multimode fiber and electrical conductors, and a remote termination node that plugs into the camera being powered.

In a PFCS, each cable is capable of powering any PoE-compliant device at a distance of up to 3 kilometers, giving the system 30 times the reach of standard PoE systems. An integrated media converter and PoE chipset work together to deliver a simple PoE or PoE Plus output in an RJ45 jack. The system incorporates DC/DC conversion technology to eliminate DC line powering calculations, and it features primary, secondary, and tertiary electrical protection for use in harsh outdoor environments as well as indoor venues.

Powered fiber cable systems significantly reduce deployment costs and time to deployment by putting control over local power back in the hands of the network operator. These cable systems simplify power negotiations, metering, and monthly recurring charges for power at the remote sites, and they streamline deployments by providing power and network connectivity at the same location.

Deploying surveillance cameras with a PFCS

With a PFCS, deploying video cameras becomes a fairly straightforward process. The PFCS acts as a long extension cord for data and power connectivity to any location desired, so the cameras can be placed exactly where they will do the most good, rather than at locations where power is available. The PFCS also eliminates the need for licensed electricians by staying within the National Electrical Code (NEC) Class 2 and Safety Extra Low Voltage (SELV) limits for low power, intrinsically safe electrical systems. Cables may be routed in the same cable pathways as Ethernet cable and other fiber-optic communications cables.

Moreover, the PFCS saves the cost of running separate data and power cables. In a south Florida golf course, for example, a design for a power/data network supporting 36 surveillance cameras was initially done using separate power and fiber cables at a cost of $981,000, but the same design with PFCS cost only $839,0000-a savings of $142,000, or 14.5 percent.

As video cameras come to support 4K and higher resolutions, installers and users can slash deployment costs, eliminate power negotiations and costs, and significantly speed camera rollouts by using a PFCS.